HOME / About ENDLESS / Made in Japan Quality

Made in Japan Quality

Always designed in-house and manufactured domestically.

All of our products are designed and developed at our company.

We conduct strength analysis via computer analysis, etc., several years in advance for thorough product quality assurance.

Also, to provide stability in our products, all products are manufactured in Japan.

At our company we have installed CNC machines and we also conduct the cutting of back plates to support all types of vehicles.

We retain dynamo testers for brake pad tests, and in 2015 we also introduce our 1st bedding machine for racing disc and pads.

Thorough quality control

When shipping, we conduct 2 types of spot quality tests: with dynamo testers and with drivers.

If we find products which do not possess the proper performance we dispose all of them.

Even during normal production, we conduct spot tests of full-scale cars and inspect via point system using test drivers.

Manufacturing and development policy prioritizing safety

The reason ENDLESS focuses on motor sports is that we have a belief that cars which cannot be used in motor sports should also not be used as ordinary road car.

In the manufacture of brakes it is impossible to handle problems after accidents have occurred. In brake manufacture it is important to include performance that seems excessive.

Careful selection of appropriate materials

ENDLESS uses iron brake brackets in its products for ordinary road car. Aluminum has the merit of light weight, but aluminum corrodes due to ionic reaction when driving. In ordinary road car which are used for a long time, it can weaken, leading to danger. We use iron because although it rusts it doesn't break.

We also consider the fact that because most users intend to use their cars for street use, using calipers made of aluminum alloy and another material curbs resonance, reducing noise.

In brake pads as well, safety is primarily important.

When asbestos first started to be viewed as an issue, we immediately started developing asbestos-free materials. In mass production we had to dispose of several thousand sets, but it became an exemplary embodiment of our corporate philosophy.

We also focus on obtain and test newly developed materials, create good relationships with major manufacturers, sometimes contract analysis of materials, as well as conducting tests in the brake dynamo which we have installed in our research and development building. By always testing new materials and also investigating materials from other fields, we are able to develop unique material quality which other companies cannot imitate.

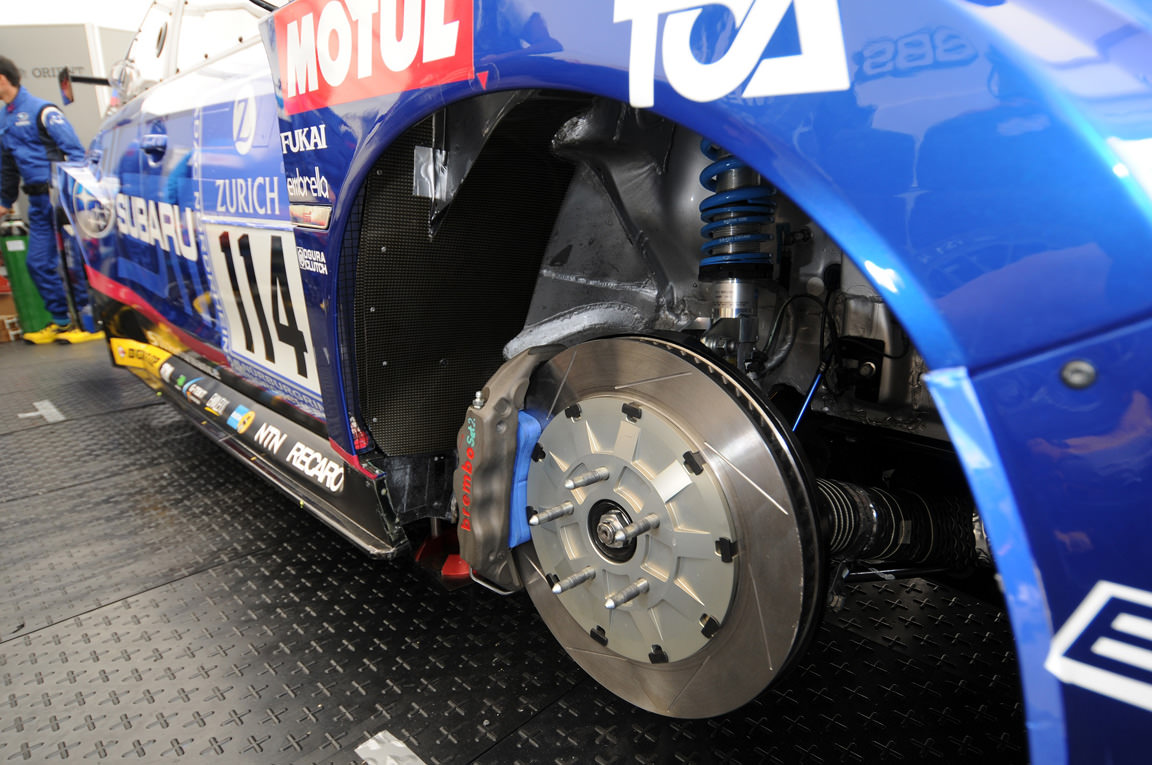

Each 1/1000mm surface accuracy

We conduct all design and development of brake rotor products in house as well, while a cooperative company which affiliate the technology manufactures the products.

We also conduct careful polishing for the final finish in house and pursue surface accuracy in each 1/1000mm.

It is generally considered with more rough accuracy, but at ENDLESS, where we put safety and security first, our quality standard is more rigorous.

In pursuit of accuracy which cannot be achieved with lathes, we adopt multiple whetstone polisher to finish all the rotors.